- Product

- Powder Processing Serise

Product Details

Product Introduction

GENERAL:

General granulation:

This machine can be divided into wet-type or dry-type granulation.

Wet-type granulation needs to add water or solvent as the adhesive during the granulation process.

Thus the drying process is essential after the granulation process.

Dry-type granulation doesn't need to add to the liquid but it can add to the binder or lubricant and as a result, the drying process is not required.

It can turn some low-density, low-specific gravity, and bad-flow materials or water-sensitive drugs into high-density, high-specific gravity, good-flow materials or the finished product which can be filled into a capsule or formed as a tablet.

Dry-type granulation process is to feed the mixed powder into the pressure screw rods to push the powder into the gap between two rollers.

Through the thrust of the pressure screw rod and the oil hydraulic pressure, it would press the flowing powder to become the powder plate.

Then 2 ratchets roll and cut the powder plate into pieces.

Finally, the pieces go through the granulator to become uniform granules.

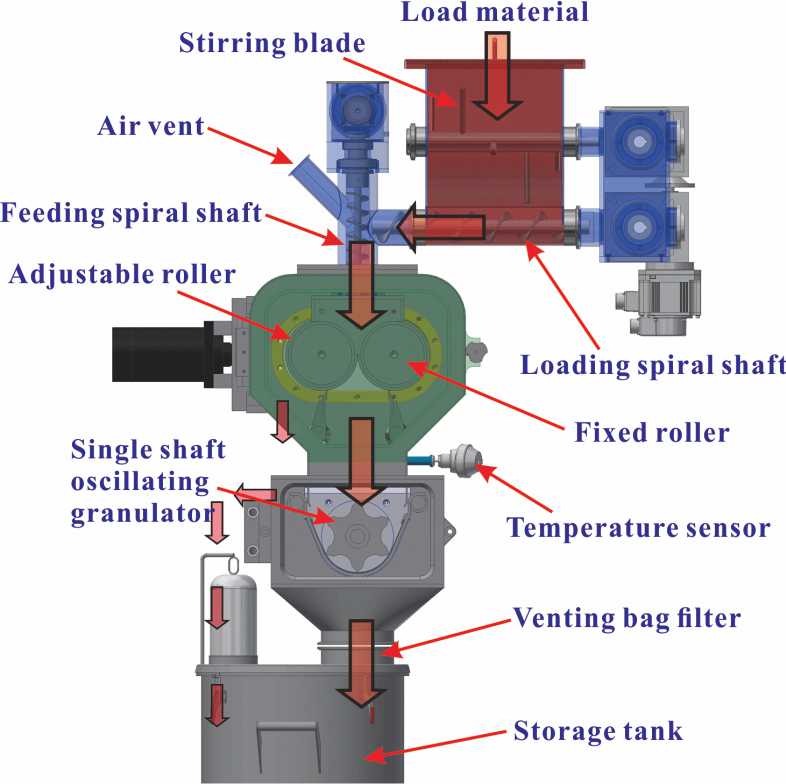

ROLLER COMPACTOR ACTION FLOW:

Put raw material in the loading hopper. The material is delivered to Roller

Device through Loading Spiral Shaft and Feeding Spiral Shaft.

Roller Device compact the raw material into slices and fall down through

Single shaft oscillating granulator to mill into finished granules.

FEATURES:

FEATURES:

|

1. Dry-type granulation process is 3 process designs into one unit which are compression, milling and granulating.

|

|

2. Dry-type granulation process is simple without adding water or solvent, therefore, the drying process is not required.

The granules made by Dry-type have stable quality, and good flow ability, it could be filled into the capsules directly or

tableting.

|

|

3. The advance pressure screw rod feeding mechanism to increase the

feeding stability.

|

Roller Rolling Part

|

|

4. Hydraulic control for the vertical rolling design assures that consistency

ofproduct hardness.

|

|

5. The changeable sieve to adjust the size of granule.

|

|

6. The rollers has the oil hydraulic pressure adjustment device and there's

water circulation cooling design for temperature lowering, this design is

suitable for heat-sensitive materials.

|

|

7. The machine is the closed design, the generated dust will not leak out during the producing procedures.

|

|

8. The whole construction is stainless steel which is easy to clean or maintain.

|

|

9. The production process can be viewed or monitoring by the transparent window.

|

|

10. The equipment can meet cGMP, PIC/S, CFR 21 part11 and the regulation & norm of US FDA.

|

|

11. Option to equip a vibration sifter, it filtrates small or undersize granules for re-granulation purpose.

|

|

12. Option to equip the automatic transferring devices to reduce the cost of labors.

|

APPLICATION:

* Pharmaceuticals: Traditional medicine, Western Medicine.

* Chemistry.

* Biotechnology, Agricultural products, Foods.

* Electronic products.

* Pigments.

TECHNICAL DATE:

| Model |

Power consumption |

Power supply |

Compressed air

consumption |

Capacity:Kgs/hr |

Size(WxLxH) (cm) |

| KDY-RC-5 |

5.6KW |

220V/380V-3PH |

N/A |

2-5 kgs/hr |

80 x 100 x 180 |

| KDY-RC-10 |

6.7KW |

220V/380V-3PH |

N/A |

7-10 kgs/hr |

80 x 100 x 180 |

| KDY-RC-30 |

9.4KW |

220V/380V-3PH |

500NL/Min (5kg/c㎡) |

15-30 kgs/hr |

80 x 110 x 200 |

| KDY-RC-70 |

12.4KW |

220V/380V-3PH |

500NL/Min (5kg/c㎡) |

40-70 kgs/hr |

110 x 100 x 205 |

| KDY-RC-100 |

14.7KW |

220V/380V-3PH |

500NL/Min (5kg/c㎡) |

60-100 kgs/hr |

110 x 120 x 205 |

| KDY-RC-150 |

21.7KW |

220V/380V-3PH |

500NL/Min (5kg/c㎡) |

100-150 kgs/hr |

140 x 160 x 350 |

| KDY-RC-200 |

24.2KW |

220V/380V-3PH |

500NL/Min (5kg/c㎡) |

150-200 kgs/hr |

150 x 180 x 350 |